Infra

Structure

“When your products have a well-thought-out packaging, you are more likely to catch the eye of your customers.”

DESIGN & PRE-PRESS

Today’s competitive world has gotten much more difficult for marketing departments. They need to provide a very substantial first impression and catch the eyes of the customer when it comes to the packaging of a product. A good designer can convey critical information about your package in a way that makes it seem as though it’s simple but compact and informative.

Our modern-day designers and technical software integrated with new econometric models can reliably determine what your target clientele thinks is aesthetically pleasing and then compile those results into one great design that will be sure to sell. Our Pre-press team is responsible for the complete process of giving our customers the best quality.

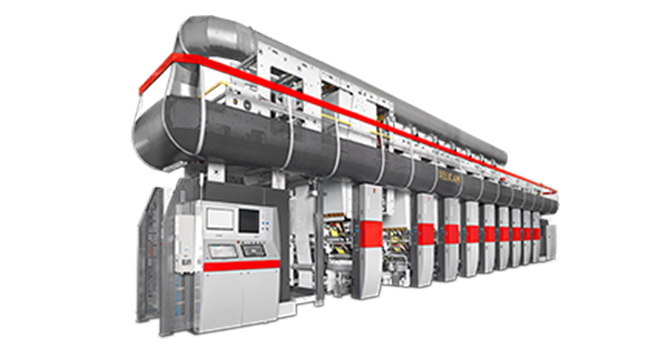

PRINTING

We have two numbers high speed automatic eight-color Roto-Gravure ARC printing machines that can print on a wide variety of substrates. From a normal printing job, we can print using specialized UV curable inks with metalized finish in rich & luminous colors.

LAMINATION

SOLVENT LESS AND EXTRUSION

Laminating is a versatile packaging technique that can be used to create a variety of packaging structures. For example, laminating two films together can create a barrier layer that protects the contents of the package from oxygen and moisture. We at Merino Polypack use solventless and extrusion lamination machines.

INSPECTION

Manual print quality inspection and strobed video web viewing systems (which only monitor tiny sections of the web) fall short of what’s needed to catch defects before they start affecting your quality. That’s why, we have installed Inspection Machines at Merino Pack that are used in inspecting various types of defects during online printing because we never compromise in quality.

SLITTING MACHINES

We at Merino Poly Pack, use the slitter machine in our industry to process the materials. The main function of this machine is to cut a big roll into smaller rolls by converting papers, films, and foils. We buy these machines and have them installed at our place where we have developed immense knowledge while handling them over the years.

DOCTORING MACHINES

The doctoring machine is a key part of the process for creating a printed, laminated product. It’s ideal for recovering any printed, laminated reels with little change over time that has been incorrectly built or discovered to be defective by a single operator. We at Merino Poly Pack, utilize this machine as part of many procedures including online printing, inspecting various types of defects during online printing, lamination, slitting operations, etc.

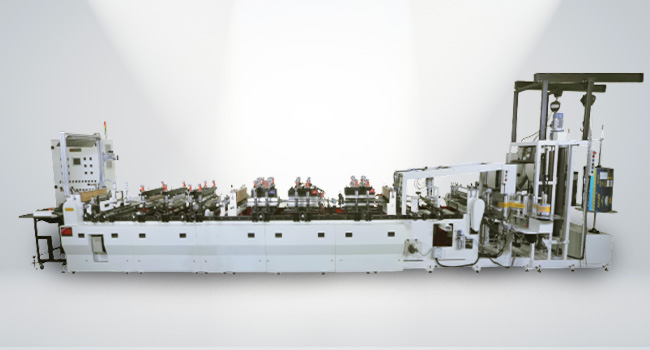

POUCH & SACK BAG MAKING

We’ve revolutionized the Indian packaging industry! From three-side sealed pouches & vacuum pouches to stand-up pouches, and more, our company is a leader in producing a wide variety of pouch formats. We start projects by assessing your needs to help you find the best solution that suits your exact needs. The new facility that’ll be added to our factories will increase our range from 200 metric tons per annum (TPA) to 400 metric tons per annum (TPA).

QUALITY & TESTING

Quality is of paramount importance to us. We use state-of-the-art test equipment to analyze everything right down to the smallest detail to ensure that every product meets our high standards of quality. We will inspect incoming materials, and semi-finished and finished products before they go out the door to fulfill our promise that only the highest quality products leave our doors.